Scope and Objectives

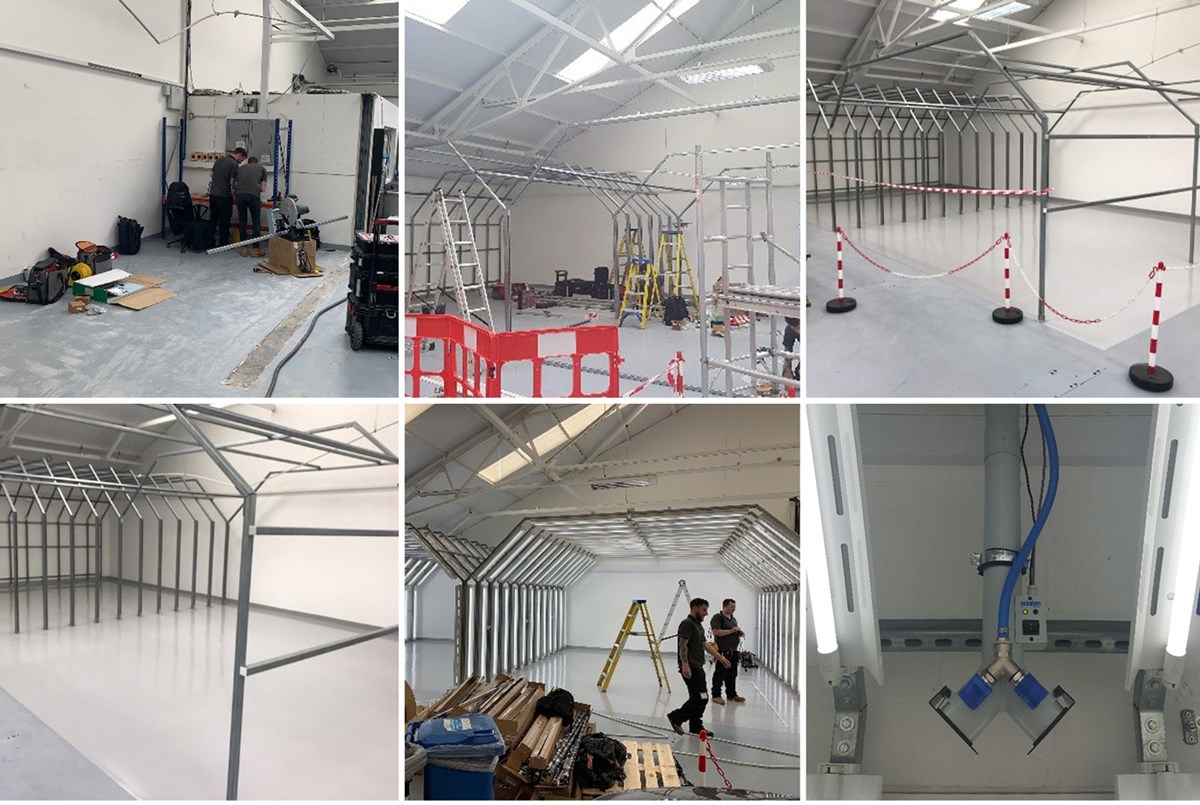

To design and install two new side-by-side light inspection tunnels for the paint shop at Newport Pagnell, based on the in-line inspection tunnels at Gaydon. Both inspection tunnels needed very high levels of lighting with controls, power, dust extraction, fans for keeping the tunnels cool and compressed air supplies. The only available area with the space was being used as a stores, so we would have to remove a wall and make good before we could start to build the inspection tunnels.

Challenges

The Paint Shop needed to be kept in use throughout the duration of the project, with the attendant health and safety considerations from vehicle and pedestrian traffic. The project planned as a six week duration to fall in line with Aston Martins requirement for delivery of the DB4 Zagato GT program.

There was no power capacity in the Paint Shop, this necessitated us installing a new sub-distribution board from a nearby main panel board in a different area.

The power consumption needed to be kept to a minimum.

Solution

Using LED tubes we designed each inspection tunnel to use a total of 78 LED tubes, fitted to a Unistrut framework. By using Unistrut we were able to keep the tunnels “open frame” thereby allowing airflow around personnel working in the tunnels. The extraction unit was installed locally to the inspection tunnels and only extracted when a tool was connected to it, again keeping the running cost down. Lighting is switched via a PIR in each tunnel, with manual override to force either off, for non-working times, or on, should a PIR fail.

The floor was painted with a two-part epoxy coating for anti-scuff properties.

Results

Project delivered early and on budget. DB4 Zagato GT is now in production and the first unit is undergoing track trials.

Excellent from start to finish, A Grade work that mirrors the standard we work to at Aston Martin Works’

Oliver Ayris ‑ Aston Martin